Why Gate Installation Services Are Crucial for School Campuses?

June 15, 2025

The Role of Gate Installation Services in Perimeter Defense

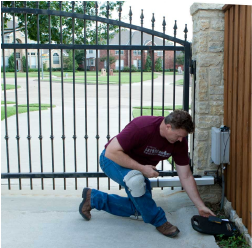

June 21, 2025Gate repair is vital to maintaining seamless access and security for both residential and commercial properties. When a gate malfunctions—whether due to mechanical wear, misaligned tracks, frayed cables, worn hinges, or failing electric components—it can lead to untimely lockouts, disruptions in daily operations, and even security vulnerabilities. Gate Repair Services play a proactive role in addressing these issues before they escalate, ensuring reliability, safety, and efficiency.

The Hidden Costs of Neglected Gates

-

Unexpected Lockouts: A small misalignment or weak spring can cause a gate to jam at the worst possible moment, leaving residents or staff stranded. Emergency lockouts are not only stressful but also can incur costly service calls and potential security risks when bypassing mechanical failures.

-

Downtime for Businesses: For companies relying on gated access—warehouses, gated offices, parking facilities—a broken gate can halt deliveries, freeze employee entry, and damage reputation. Lost time and inconvenience directly affect revenue and workflow.

-

Security Compromises: Malfunctioning locks or keypads offer an unintended invitation to intruders. Even intermittent failures reduce confidence in perimeter security, which can undermine other protective measures.

-

Rapid Deterioration of Components: Minor misalignments overload hinges, tracks, and motors, accelerating wear. Components strained beyond tolerance quickly degrade, turning a simple fix into a major overhaul.

-

Higher Repair Expense: Delaying attention often means minor fixes multiply into major jobs—motor replacement, track realignment, or structural gate rebuilds. Early intervention is significantly less costly than full replacements.

Core Reasons Proactive Gate Repair Matters

Precision in Mechanical Alignment

Ensuring that hinges, rollers, and tracks are aligned prevents undue stress. Smooth operation preserves hardware integrity and extends equipment lifespan.

Lubrication and Corrosion Management

Regular greasing of pins and rollers combats friction and wear. Rust-prone environments (e.g. coastal or humid areas) benefit from anti-corrosion treatments and protective coatings to avoid deterioration.

Timely Replacement of Worn Parts

Springs, rollers, and cables should be inspected and replaced before failure. Proactive replacement minimizes downtime and avoids emergency service calls, which often come at a premium.

Controller and Sensor Calibration

Electric gate automation relies on well-calibrated sensors and responsive controllers. Routine checks prevent erratic behavior, false triggers, or shutdowns that lock out users or deny access.

Safety Mechanism Validation

Pressure edges and photo eyes prevent injury by detecting obstructions. A malfunctioning safety sensor may deactivate unmanned operation or trigger lockout protocols—proper calibration avoids inconvenience while maintaining compliance.

Benefits of Regular Gate Maintenance & Repairs

-

Uninterrupted Access: Daily routines and business operations run smoothly when gates consistently open and close as intended.

-

Cost Efficiency: Small preventative fixes are always less expensive than major structural or full-system replacements.

-

Enhanced Safety: A mechanical or electronic failure in a gate can cause serious injuries to users or passersby. Functioning sensors and mechanisms protect both lives and equipment.

-

Improved Asset Lifespan: Routine upkeep delays complete gate replacement, preserving capital investment.

-

Regulatory Compliance: Many automated gate systems must meet safety standards; ongoing maintenance ensures inspections are passed and certifications are maintained.

Real-World Scenarios: When Repair Saves the Day

-

A homeowner suddenly can’t exit their driveway in the morning due to a sheared bolt; a quick repair call gets the gate operating before daylight rush.

-

A commercial complex experiences intermittent gate failure during peak hours—techs diagnose controller glitches and update firmware to restore reliability.

-

Event planners installing temporary access gates rely on rapid repairs: technicians grease rollers and replace worn tracks overnight to prevent delays during client arrival.

Recommended Maintenance Workflow

-

Visual & Manual Inspection: Scan the gate for signs of wear—loose bolts, rust, frayed cables—and test for wobble or friction.

-

Functional Testing: Operate the gate with automation on and off. Verify sensors, auto-reverse, and remote-control response.

-

Lubrication: Apply quality lubricant to moving parts—hinges, rollers, chains—balancing between sufficient lubrication and avoiding excess buildup.

-

Component Assessment: Inspect cables, springs, and rollers. Replace any showing significant wear or damage.

-

Electrical & Safety Check: Validate sensor positioning and behavior, test keypads and remotes, confirm stable controller programming.

-

Final System Trial: Run multiple open/close cycles, including manual release, to ensure smooth, reliable operation.

When to Act: Warning Signs to Watch

-

Jerky movement or unusual noises during gate operation

-

Sensor misreads or intermittent obstructions

-

Remote control or keypad glitches

-

Visible rust buildup or peeling paint

-

Noticeable delays or resistance during opening/closing

Addressing these early prevents escalation—often turning a modest service call into a long-term malfunction requiring major expense.

Balance: Repair vs. Full Replacement

Not every problem justifies a new gate. Consider replacement when:

-

The base structure shows deep corrosion or metal fatigue

-

The gate’s design doesn’t support modern automation standards

-

Upgrading to a more secure or aesthetic option makes sense

But more often, precision repair sustains functionality at a fraction of replacement cost, particularly for high-quality gates built to last.

Gate Maintenance Checklist

| Task | Frequency | Objective |

|---|---|---|

| Visual inspection | Monthly | Catch wear or misalignment early |

| Lubrication of moving parts | Quarterly | Reduce friction and prevent rust |

| Safety sensor testing | Quarterly | Ensure accurate auto-reverse action |

| Manual release test | Semi-annually | Verify emergency operation readiness |

| Controller & keypad check | Semi-annually | Maintain electronic reliability |

| Component replacement | As needed | Replace springs, rollers, cables |

Why choose LA Gates Repair?

-

Dedicated technicians using quality parts and professional-grade tools

-

Rapid response to lockouts—inconvenience minimized, access restored

-

Expert handling of mechanical and electronic components

-

Preventative service plans tailored for residential and commercial clients

-

Commitment to safety protocols and durable repairs

For those who value seamless access and lasting peace of mind, LA Gates Repair delivers dependable results every time.